What is LGS?

LGS (Light Gauge Steel) is a construction method that uses cold-formed steel members to create structural frameworks for buildings.

Applications

Commonly used in single-family homes and multi-family row houses up to three stories, LGS is increasingly popular in commercial buildings for its versatility and performance.

Growing Popularity

LGS framing is rapidly growing worldwide as builders prefer its advantages over traditional methods.

LGS Characteristics

Manufacturing Process

LGS begins as galvanized sheet steel shipped in coils from mills, then shaped into structural members without heat application

Profile Formation

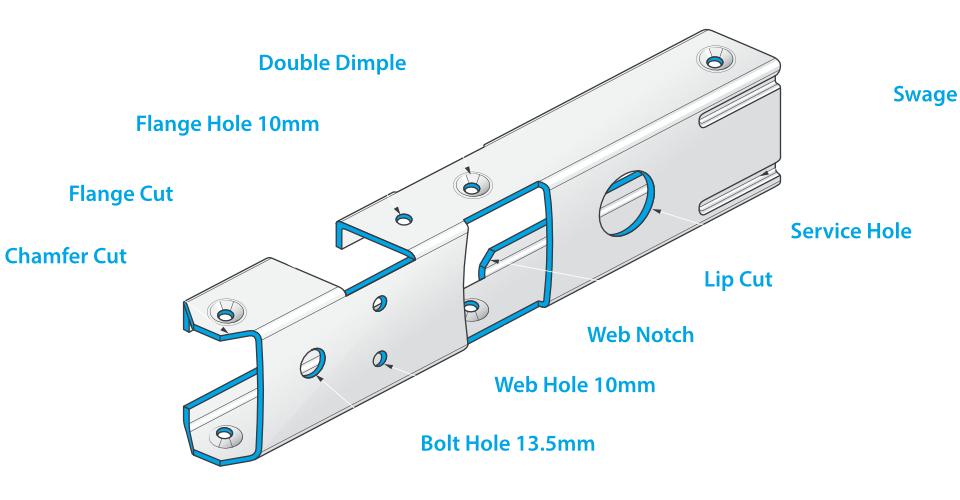

The cold-forming process creates C-sections, tracks, and other shapes, enhancing strength through the work-hardening effect

Material Specifications

Loadbearing members comply with ASTM standards, featuring minimum yield strengths of 230-340 MPa depending on thickness

Corrosion Protection

LGS members include metallic coatings (typically zinc or aluminum-zinc) that protects the underlying steel from deterioration.

Components of an LGS Frame

-

Loadbearing walls carry vertical loads from construction above or lateral loads from wind. Non-loadbearing walls act as partitions. Components include C-shaped wall studs, top and bottom tracks, and bracing.

Design Factors: Walls are divided into loadbearing (structural) and non-loadbearing (partition) categories; selection of members is based on various structural requirements.

Assembly Methods: Tilt-up construction enables efficient horizontal framing prior to vertical placement, with special backing needed for drywall at corners.

Structural Integrity: Horizontal bridging prevents twisting; diagonal X-pattern bracing provides resistance against lateral forces, and structural sheathing enhances racking resistance.

Performance Benefits: Non-combustible steel offers excellent fire resistance when sheathed correctly, while cavity insulation improves sound control with higher STC ratings.

.

-

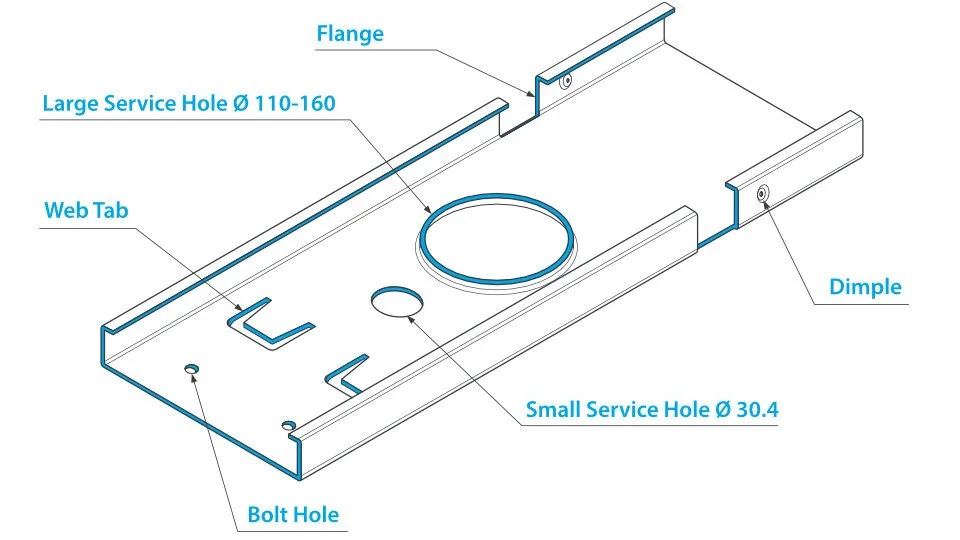

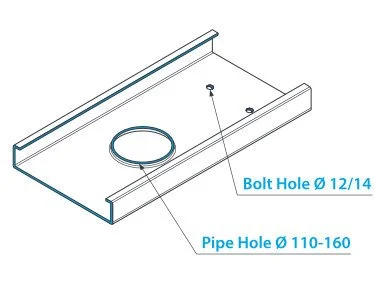

Made up of C-sections as joists connected to C-section bearers. Floor joists can be designed from various C-section sizes based on specific loading parameters.

Load Transfer: LGS floors efficiently distribute both dead and live loads, ensuring structural stability by resisting deflection and minimizing vibration.

Beam Options: Structural steel and built-up LGS beams deliver excellent support; steel beams need 89mm minimum end support, while built-up beams use juiced and track members secured with screws at 610mm intervals.

Joists & Stability: Precision-engineered joists and closure channels enhance installation security, with double joists providing support for parallel partition walls and solid blocking preventing rolling at a maximum spacing of 2400mm.

Assembly Benefits: Subfloors offer lateral bracing for joist flanges, waterproof adhesives bolster system rigidity, and clip angle connectors secure precision floor openings.

-

Generally a steel truss system designed for metal sheets or tiles. Can accommodate all types of roof designs (hip, gable, dutch gable) and are screwed directly onto the wall frame

Framing Options: Choose between custom "stick built" rafters or pre-engineered truss assemblies for spanning exterior walls.

Environmental Resistance: Designed to endure wind and snow loads of up to 2.5 kPa without needing specialized design.

Joists & Installation: Ceiling joists need top flange bracing. Roof joists are installed like floor systems, incorporating web stiffeners.

Wall Connections: Connections are made using wood or steel top plates, with double wood plates allowing for the elimination of in-line framing.

-

Self-drilling, self-tapping screws serve as the primary connection method for LGS framing. These specialized fasteners eliminate the need for pre-drilling and ensure strong, reliable joints between steel members.

Self-Drilling

Strength & Reliability

Installation Efficiency

Connection Versatility

No Welding Required

-

Flat strap bridging provides essential rotational restraint for loadbearing studs, preventing twisting under load and enhancing overall structural stability.

Structural Integrity

Load Distribution

Lateral Stability

Reduces vibration and deflection

Installation Efficiency

-

Critical reinforcement components installed where concentrated loads act on floor joists or track sections, preventing local buckling and ensuring proper load transfer at these high-stress points.

Critical Reinforcement

Load Distribution

Structural Integrity

Material Optimization

Connection Enhancement

-

Purpose-designed connectors that create strong joints between different structural elements such as floor joists to headers, lintels to king studs, or headers to trimmers.

Versatile Connectors

Assembly Efficiency

Structural Performance

Cost Reduction

Design Flexibility

Integrating MEP Systems with LGS

HVAC Systems

Pre-punched service holes allow efficient routing of ducts. Straight walls and square corners provide predictable pathways, making pre-assembly more feasible.

Installation Benefits

Reduced on-site modifications and faster installation times translate into lower labor costs and accelerated project timelines for all MEP contractors.

Electrical Systems

Steel's non-combustible nature enhances fire safety. In case of electrical faults, the conductive steel frame trips circuit breakers instantly, preventing hazards.

Plumbing Systems

Factory-provided pre-punched holes eliminate on-site drilling. Dimensional stability ensures pipes remain securely fastened within stable wall cavities.